Kupisa-kumashure kunoreva nzira yekudzoreredza yekukotamisa zvigadzirwa zvakaremara, zvakapinzwa, zvigadzirwa zvedecarburized uye.tungsten carbide zvigadzirwaane pores akawandisa.(1) Kudzoserwa kumashure kwezvakapinzwa uye decarburized zvigadzirwa.Carburizing uye kumashure-kupisa kunowanzo shandisa yakakwirira-tembiricha calcined graphite particles kana musanganiswa wegraphite particles uye Al2O3 poda sepakati, uye kuita kumashure-kupisa pasi pekudzivirira kwehydrogen.

Decarburization uye backburning kazhinji kushandisa Al203 upfu calcined panguva yepamusoro tembiricha kana musanganiswa Al203 upfu uye yakanaka W poda sezvo svikiro, uye backburning kunoitwa pasi hydrogen kudzivirirwa.

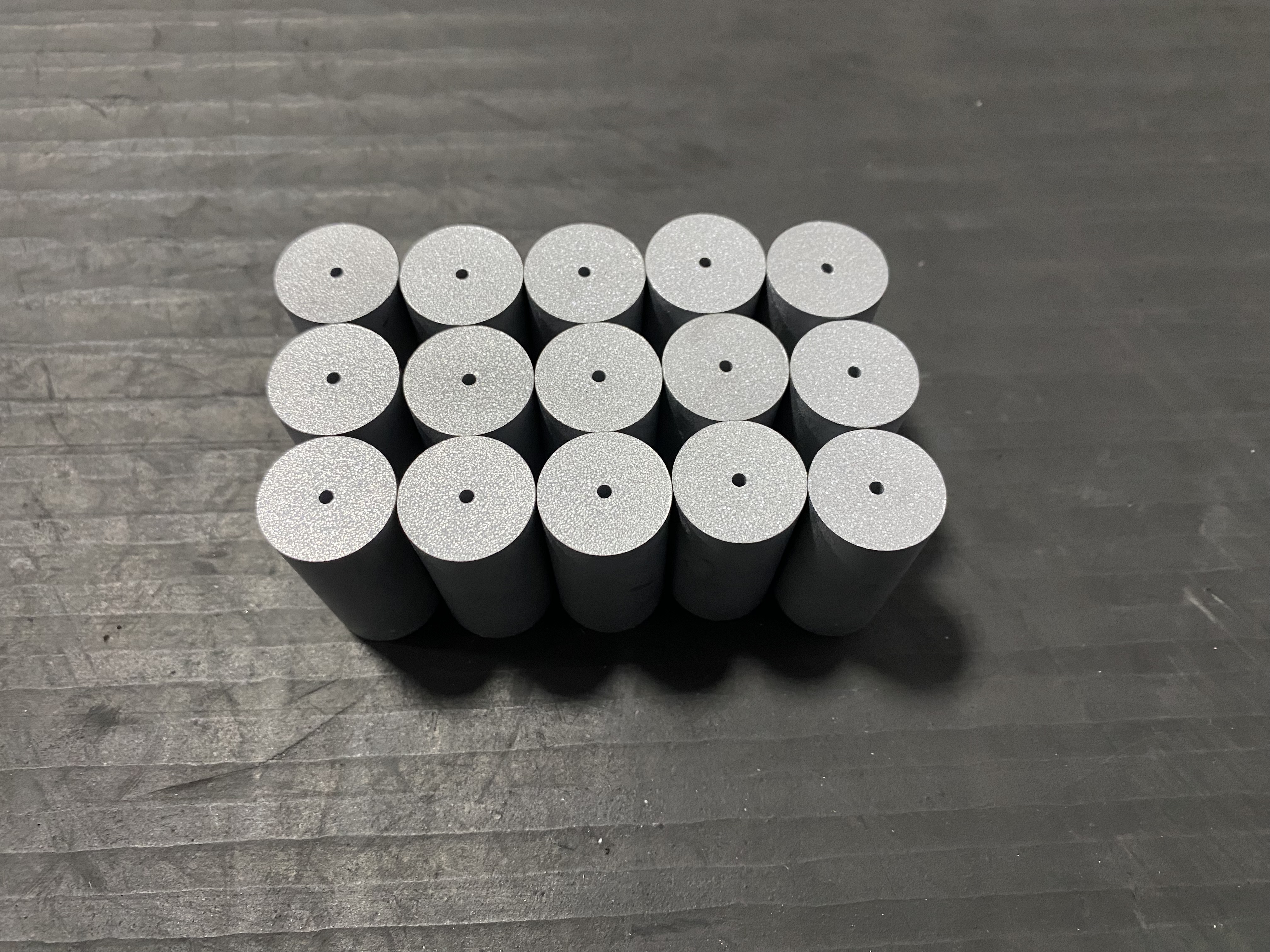

(2) Iyo porosity inopfuura mwero uye inopisa kumashure.Kana iyo porosity ye tungsten carbidesintered zvigadzirwa (pores kwete akakurisa kupfuura 25 μm) inodarika mwero, yekumanikidza sintering choto inogona kushandiswa kumanikidza sintering nekumanikidza kweanenge 10MPa.Kupisa kwekupisa kunofanira kunge kuri 20 ° C kuderera pane yekutanga sintering tembiricha yechigadzirwa.Kugadziridza pamitsipa yepamusoro uchishandisa inopisa isostatic kudzvanya kunoshanda zvakanyanya.

(3) Kururamisa.Backburning inoitwa nekuisa kumanikidza uye kushandisa hydrogen kudzivirira kana vacuum state pane tembiricha yakakwira zvishoma pane tembiricha ye eutectic.Huremu hwekumanikidza hunogona kugadziridzwa kana tembiricha yekururamisa inogona kuwedzerwa zvinoenderana nemamiriro ekugadzirisa echigadzirwa, asi tembiricha yekururamisa haifanirwe kunge yakakwira kupfuura yekutanga sintering tembiricha yechigadzirwa.

Nguva yekutumira: Jan-07-2024