Ngatitangei nemichina yekugadzirisa:

1, iyo yemukati groove, gomba, yemukati nekunze shinda uye zvimwe zvekugadzirisa zvinhu: neaya maitiro echimiro, isu kazhinji tinoda kushandisa yakakosha CNC muchina chishandiso - ceramic engraving uye milling muchina, ichi muchina chishandiso chinoita senge chine hukama ceramics, kutaura zvazviri, ichi chishandiso chemuchina chinoshandawo pakugadzirisa simende carbide.Nekuti kana uchigadzira carbide, guruva rakawanda richagadzirwa, uye kukuvadzwa kweiyi huruva kumuchina wemuchina kuchiri kwakanyanya.Iyo yechinyakare CNC yakaoma kurwisa aya maguruva akatsetseka, nekudaro zvinotungamira mukusakara uye kubvaruka kwescrew pamwe nezvimwe zvikamu.Iyo ceramic engraving uye muchina wekugaya unogona kugadzirisa chiitiko ichi zvakanyanya, nekuti iyo ceramic yekuchera uye muchina wekugaya une akakwana ekudzivirira matanho, ayo anogona kunyatsoparadzanisa carbide poda kubva kune chaiyo zvikamu.

2, Kugadziridza midziyo yendege nematanho: Kana uchigadzira ndege huru nematanho pamusoro pecarbidezvinhu, zviri nani kushandisa grinders yepamusoro, iyo ine yakakwirira yekugadzirisa kururama uye kushanda.

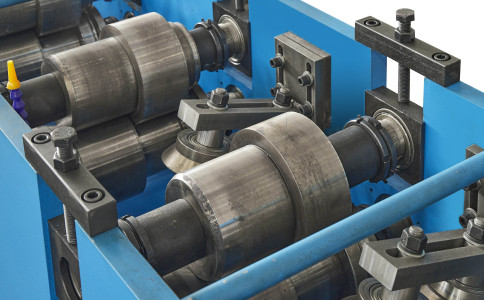

3, Kugadziridza michina yedenderedzwa rekunze: muchina wekukuya wekunze, muchina wekugaya usina pakati, nezvimwe zvinogona kushandiswa pakugadziridza carbide yekunze denderedzwa.

Machining nzira dzesimende carbide:

1, Kugadzira tambo dzemukati nekunze: Iyo tambo yekugadzirisa ye simende carbide inofanira kugadziriswa neshinda yekugaya, kwete nepombi zvakananga.

2, Kugadziriswa kwemukati groove: dhaimondi rinokuya tsvimbo inofanira kushandiswa, uye uwandu undercutting inodzorwa dzinenge 2-3 waya nguva imwe neimwe, iyo inofanira kugadziriswa maererano zvakanakira nezvayakaipira dhaimondi grinding tsvimbo.

3, Magetsi discharge machining (muwaya, kunonoka kufamba waya, kukurumidza kufamba waya kugadzirisa)

4, Welding processing: mhangura welding, sirivha welding processing.

5, Kukuya kugadzirisa: kukuya kusina pakati, kukuya kwemukati, kugaya ndege, kugaya kugadzirwa, vhiri rekukuya rinoshandiswa rinowanzo kugaya dhaimondi, zvichienderana nemaitiro ekusarudza.

6, Laser kugadzirisa: laser kucheka uye kuumba, kubaya, asi ukobvu hwekucheka kunosungwa nesimba remuchina welaser.

Nguva yekutumira: Jun-22-2023