WC-Co hard alloys ane yakanaka microwave kuchinjika.Munguva yekuita sintering, nzira dzekurasika dzinoshanda munzvimbo yakaderera tembiricha dzinonyanya kurasikirwa nekuzorora kwepolarization uye kurasikirwa kwemagineti, nepo munzvimbo yepamusoro tembiricha iyo alloy inotora microwave simba.Kunyanya muchimiro chekurasikirwa kwedielectric uye kurasikirwa kwemaitiro.

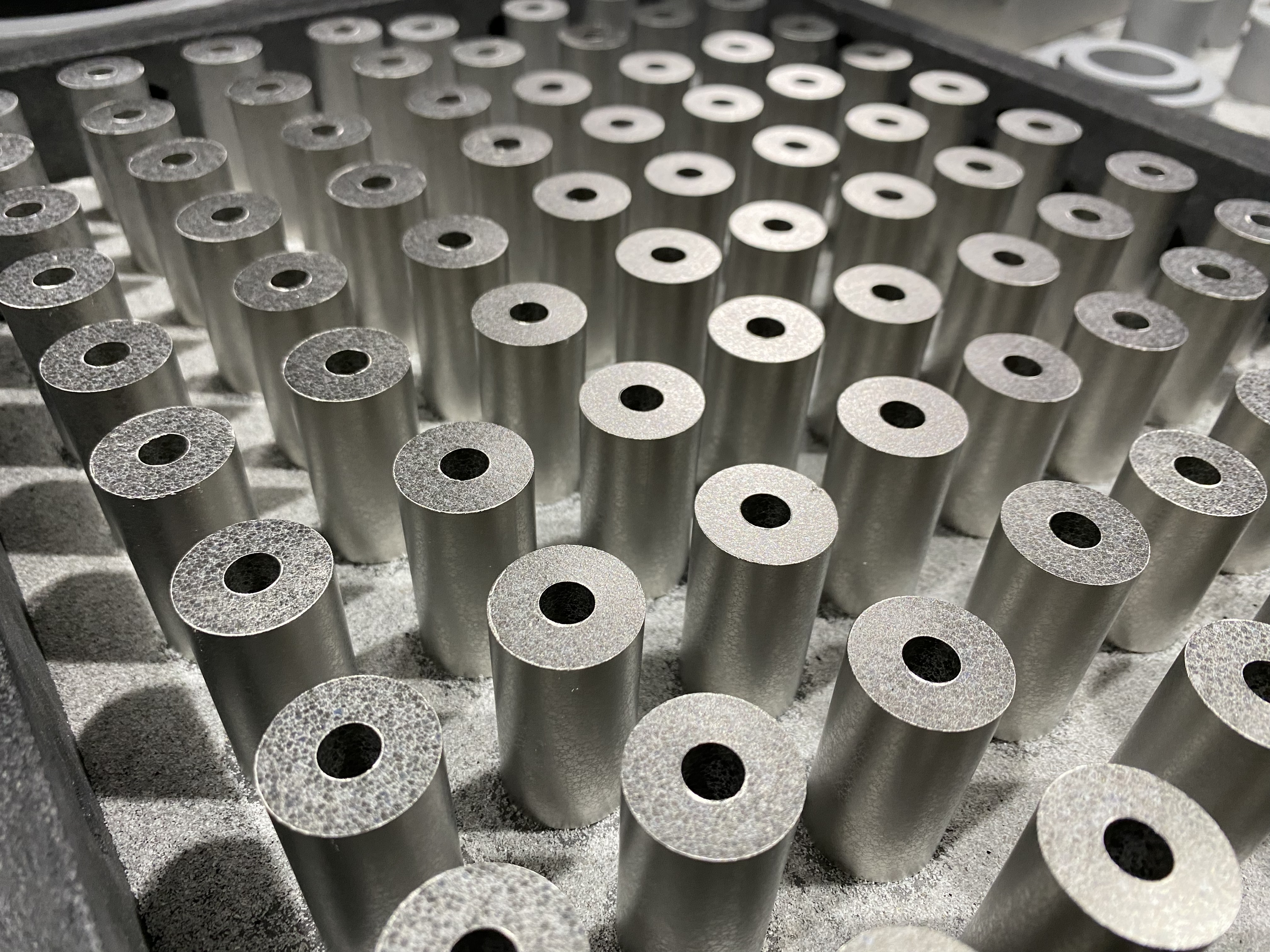

Thealloypamwe nekuwedzera kwe0.4% VC uye 0.2% Cr3C2 (chikamu chezhinji) sezvinhu zvekubatsira zvine basa rakanakisisa;kushandiswa kwevacuum microwave sintering kunovandudza zvakanyanya kushanda kwealloy.Kushandisa multi-cavity microwave sinteringWC-8Co, inopiswa pa 1400 ° C pasina kuchengetedza kupisa.Density inogona kusvika 14.71g/cm, iyoHRA inosvika90.3, uye chimiro chakafanana.

Microwave sintering tekinoroji inogona kushandiswa kugadzirira ekupedzisira-akanyoro cermets ane zviyo zvakanaka, chimiro chakafanana uye kuita kwakanakisa.Sezvo kupisa kunopisa kunowedzera, shrinkage, density, flexural simba uye kuoma kwe-ultra-fine cermets kunotanga kuwedzera uye kuderera, nehuwandu hwehuwandu hunoonekwa pa1500 ° C;kwakakodzera microwave sintering process ye-ultra-fine cermets Mushure mekuchengetwa pa1500 ° C kwemaminetsi makumi matatu, iyo flexural simba uye kuomarara kukosha ndeye 1547MPa uye 90.6HRA zvichiteerana, izvo zvinowedzerwa ne24.0% uye 0.7% zvakateerana zvichienzaniswa neyakajairwa sintering.

Nguva yekutumira: Jan-03-2024