Kuridza kwesimende carbideis liquid phase sintering, kureva kuti re-bonding phase iri mu liquid phase.Mabhii akatsikirirwa anopisa kusvika 1350°C-1600°C muchoto chevacuum.Iyo mutsara shrinkage yeakatsikirirwa billet panguva yekunyura inenge 18% uye vhoriyamu shrinkage inotenderedza 50%.Kukosha chaiko kweshrinkage kunoenderana nehukuru hwehupfu uye kuumbwa kweiyo alloy.

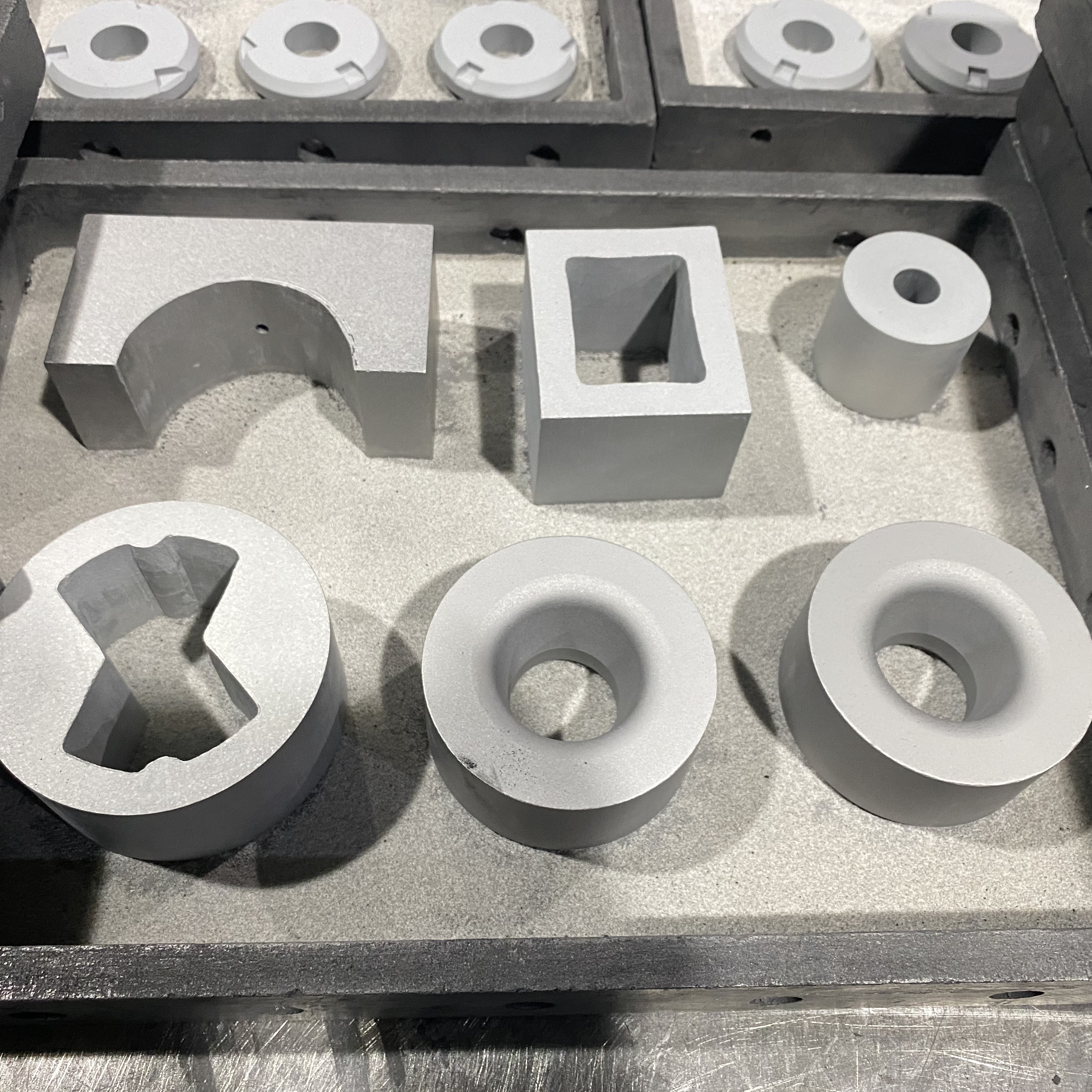

Sintering ofsimende carbideIyo yakaoma physicochemical process, iyo inosanganisira plasticizer kubviswa, degassing, solid phase sintering, liquid phase sintering, alloying, densification, dissolution precipitation uye mamwe maitiro.Iyo yakatsikirirwa billet inoputirwa pasi pemamiriro ezvinhu chaiwo kuti iite chigadzirwa chine imwe kemikari, chimiro, zvivakwa uye chimiro uye saizi.Aya maitiro maitiro anosiyana zvakanyanya zvichienderana neiyo sintering unit.

Cemented carbide vacuum sintering inzira iyo sintering inoitwa isingasviki 1 atm (1 atm = 101325 Pa).Sintering pasi pevacuum mamiriro ekudzikisira zvakanyanya kudzivirirwa kwe densification neiyo adsorbed gasi pamusoro pehupfu uye gasi mumapores akavharwa, ayo anobatsira pakupararira uye densification, inodzivirira kuita pakati pesimbi uye zvimwe zvinhu mumhepo panguva yemhepo. sintering process, uye inogona kuvandudza zvakanyanya kunyorova kweiyo mvura viscous chikamu uye yakaoma chikamu, asi vacuum sintering inofanira kutarisisa kudzivirira kupera kwekubuda kwecobalt.Vacuum sintering inogona kukamurwa kuita nhanho ina, kureva nhanho yekubvisa plasticizer, pre-sintering nhanho, tembiricha yekupisa sintering uye nhanho yekutonhora.

Iyo plasticizer yekubvisa nhanho inotanga kubva mukamuri tembiricha uye inokwira kusvika ku200 ° C.Iyo gasi yakashambadzirwa pamusoro pehupfu hwehupfu mubillet inoparadzaniswa kubva pamusoro pezvikamu pasi pechiito chekupisa uye inopukunyuka kubva mubillet nguva dzose.Iyo plasticizer mubillet inopisa uye inopukunyuka kubva mubillet.Kuchengeta yakakwira vacuum level inobatsira kuburitswa uye kupukunyuka kwemagasi.Mhando dzakasiyana dzeplasticizers dzine hunhu hwakasiyana painopisa, saka iyo plasticizer yekubvisa maitiro inofanirwa kugadzirwa zvinoenderana nemamiriro chaiwo.

Plasticizer yekubvisa maitiro inofanirwa kutariswa zvinoenderana nemamiriro chaiwo ebvunzo.Iyo yakawanda plasticizer gasification tembiricha iri pazasi 550 ℃.

Pre-sintering nhanho inoreva tembiricha yekupisa isati yatanga, kuitira kuti kemikari okisijeni muupfu zvidimbu uye kabhoni kuderedza kuita kuti ibudise kabhoni monoxide gasi ichisiya iyo press billet, kana gasi iri risingakwanisi kubviswa kana chikamu chemvura chikaonekwa, ichava yakavharwa pore yakasara mu alloy, kunyange kana yakamanikidzwa sintering, zvakaoma kubvisa.Kune rimwe divi, kuvepo kweiyo oxidation kuchakanganisa zvakanyanya kunyorova kwechikamu chemvura kusvika kune chakaoma chikamu uye pakupedzisira kukanganisa densification process ye simende carbide.Pamberi pechikamu chemvura chisati chaoneka, chinofanira kunge chakadzimwa zvakakwana uye chepamusoro-soro chinogona kushandiswa.

Sintering tembiricha uye sintering nguva inokosha muitiro parameters nokuda densification billet, kuumbwa homogeneous chimiro uye kuwana zvinhu zvinodiwa.Iyo tembiricha yekupisa uye sintering nguva zvinoenderana nekuumbwa kwealloy, saizi yehupfu, kukuya simba remusanganiswa uye zvimwe zvinhu, uye zvakare inotongwa neyakajairwa dhizaini yezvinhu.

Nguva yekutumira: Jun-08-2023