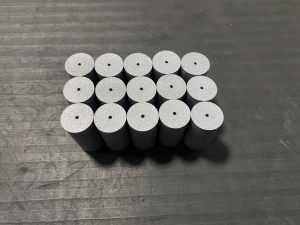

Fastener Indasitiri Shandisa Tungsten Carbide Cold Forging Die

1. Chinese fekitori inonyanyogadziriswa nekugadzira, ISO certification.

2. Multiple saizi uye mhando dziripo nokuda OEM.

3. Yakagadzirwa ne100% yepakutanga yemhando yepamusoro zvinhu

4. Nyanzvi yekugadzira timu, kukurumidza kuendesa

5. Free professional after-sales service uye technical support

Tungsten carbide inotonhora musoro inofa inoshandiswa zvakanyanya kugadzira kupera kufa kukanda mould, punch inofa, waya yekudhirowa kufa, muchina mold, inofambira mberi kufa, extrusion kufa, press mold, mold parts, trimming die, kutonhora musoro kufa, kuumba mold, kutonhora kuumba kufa. etc.

| Tungsten Carbide Cold Forging/heading Inofa | |||||

| MaGrades | Density | TRS | Kuoma | Performance & application inokurudzirwa | |

| g/cm³ | MPa | HRA | |||

| YG11 | 14.4 | ≥3000 | 88.5 | Kugadzira kana kudhinda kunofira simbi hupfu uye hupfu husina simbi. | |

| YG15 | 14 | ≥3400 | 87.5 | Yekugadzira dhizaini inofa yemachubhu esimbi uye tsvimbo pasi peHigh compressibility ratio;kurovera, kutsika, kugadzira maturusi pasi pekunetseka kukuru. | |

| YG20 | 13.5 | ≥3800 | 85.5 | Pakugadzira zvidhindo zvinofa zvewachi, maplates ezviridzwa, magaba ebhatiri, mabhora madiki esimbi, screws, screw caps. | |

| YG15C | 14 | ≥4000 | 86.5 | Zvekubooresa mafuta koni, cheka matombo akapfava uye akaomarara; kubvongodza uye kucheka huni dzakaoma nechando, huni dzakapfava nehuni hwepakutanga. | |

| YG16C | 13.9 | ≥3500 | 85.5 | Impact resistance forging inofa. | |

| YG18C | 13.7 | ≥3600 | 84.5 | Impact resistance forging inofa, hot-press forging inofa uye rollers. | |

| YG20C | 13.5 | ≥3800 | 83.5 | Inofa nekuda kwekupfeka kusagadzikana kana kukanganisa kusagadzikana application. | |

| YG22C | 13.3 | ≥4000 | 83 | Kugadzira nzungu kunofa uye yakanyanya kusimba kuramba kufota kunofa. | |

| YG25C | 13.1 | ≥4250 | 82.5 | Stainless bolt header inofa nema rollers. | |

Kufananidza zvinhu → Kukuya Bhora → Yakasanganiswa WC uye Cobalt Simba → Kudzvanya → HIP Sintering Mavira → Kuongorora QC → Kurongedza

| Type | OD | ID | H | Kushivirira | ||

| OD | Id | H | ||||

| φD10~14×φd | 10~14 | 1.0~5.0 | 15~40 | D×+3% | d×-3% | H×+3% |

| φD15~24×φd | 15~24 | 1.5~8.0 | 20~60 | |||

| φD25~40×φd | 25~40 | 1.5 -25 | 30~60 | |||

| φD42~95×φd | 42~95 | 2.0~50 | 20~95 | |||

Kune chero mamwe saizi isu tinokwanisa kugadzira-yakagadzirwa zvinoenderana nezvinodiwa nevatengi kana kudhirowa.

1. Tichaedza zvatinokwanisa kuti tipindure chikumbiro chevatengi vedu mukati me24hours.

2. Tichachengetedza kutaurirana kwakanaka uye kwakanaka nevatengi vedu.

3. Isu tinopa yekutanga-kirasi yemhando yekudzora uye mushure mekutengesa masevhisi.

Isu tichaendesa mitoro inogadzirwa mukati me30days mushure mekubhadhara pasi, nepo, Kana paine zvikumbiro zvesoecific panguva yekutumira.Tinogona kuita shanduko maererano nechikumbiro chevatengi, saka nguva pfupi yekutumira inowanikwa zvachose.

Kazhinji 30% T / T pachine nguva, chiyero 70% isati yasvika.Uyewo inogona kuchinja maererano nechikumbiro chevatengi.

Isu tinogadzira zvinhu mumhando dzakasiyana uye saizi kuti ienderane nezvinodiwa nevatengi vedu chaizvo, vangave vachida mabhuraki kana mashiti, masilinda, mabhengi, matipi kana mazino.